What is the main cause of plastic pollution?

Qatar has one of the fastest-growing economies in the world and also one of the highest per capita rates of waste generation in the world. It has more than 1.5 kilograms of waste produced every day. Major sources of pollution include municipal plastic waste, industrial waste, tire wear, construction, and agricultural waste.

Municipal solid waste management is a challenge for Qatar, which generates more than 2.6 million tons of municipal solid waste annually and is expected to continue to experience a significant increase in the rate of solid waste growth over the forecast period.

How does plastic pollution affect humans?

Researchers have detected nanoplastic pollution for the first time in polar regions, suggesting that the tiny particles are now widespread around the world, especially in oceans and coastal areas. Plastic is part of a mixture of chemical pollution that spreads across the planet, exceeding the limits of human safety. Plastic pollution has been found from Mount Everest to the depths of the ocean. People are known to inadvertently ingest microplastics through eating or breathing, and another recent study found that these particles can cause damage to human cells.

There is evidence that human organs and tissues can absorb trace amounts of nanoplastics, which can cause subtle damage to the body. Nowadays the world is trying to find and explore ways to recycle plastics to save our environment and future generations.

What is Qatar doing to stop pollution?

Qatar Airway Catering Company recycled millions of kilograms of plastic waste

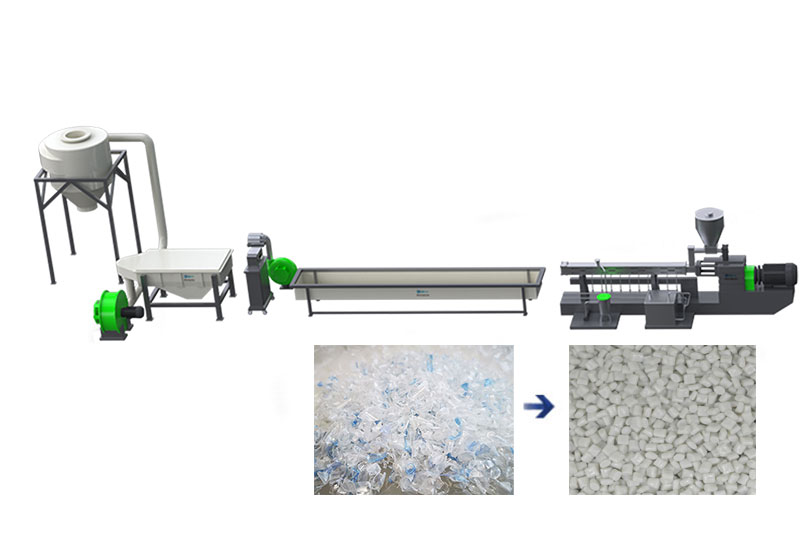

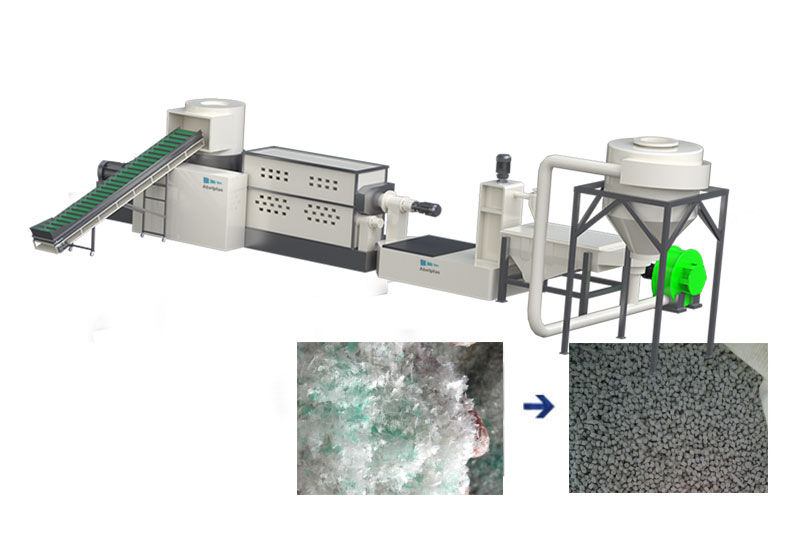

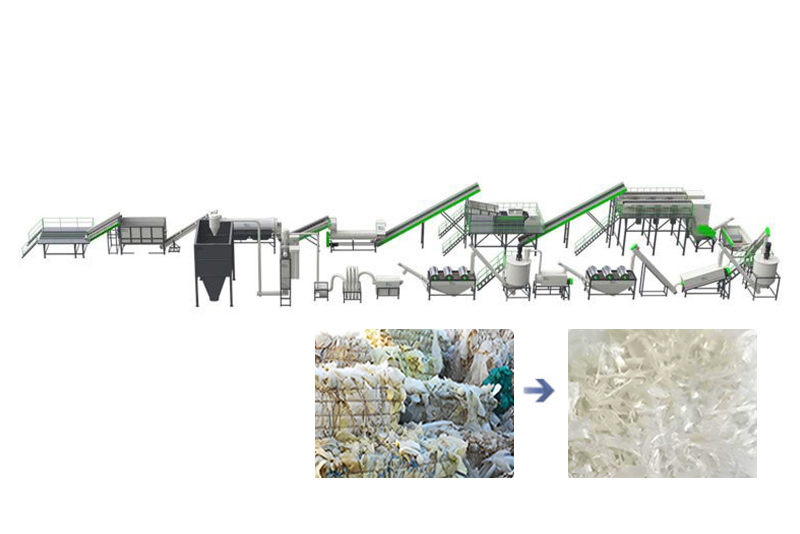

Qatar Airways Catering Company (QACC) has made significant achievements in promoting environmental sustainability through its waste recycling program, which not only reduces the impact of waste on the environment but also succeeds in transforming these resources into useful commodities and promoting a circular economy.

Over the past year, QACC has recycled more than one million kilograms of plastic waste, which has been reused, covering a wide range of materials such as cardboard, chemical plastic drums, plastic water bottles, and waste paper, which have been processed and reintroduced into the marketplace, reducing the demand for raw materials as well as alleviating the pressure on landfills and environmental pollution.