Video

Detailed Image

Machine Parameters

Recycled material is as follows

Package&Shipping

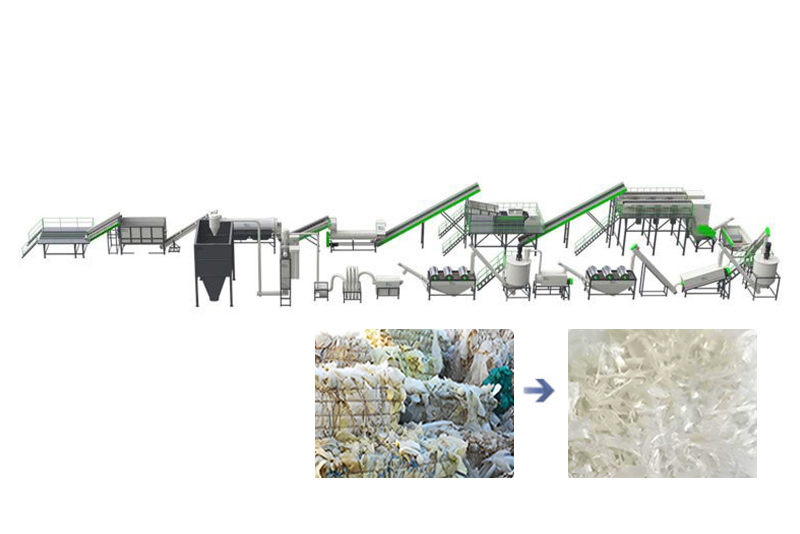

Production Lines Flow Chart

Belt Conveyor

The belt conveyor transports the plastics to the crusher, which can directly and automatically transport them. All contact with raw material parts is made of stainless steel, and the inverter controls it.

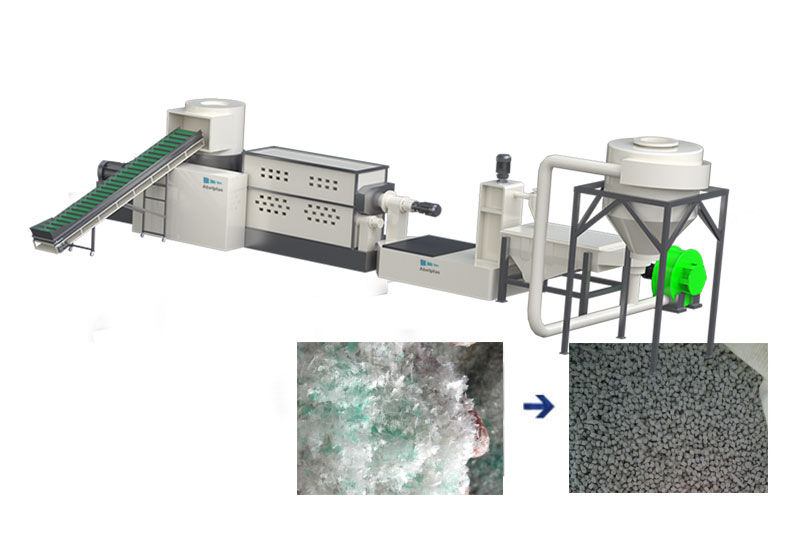

Crusher

To crush material into small sizes. Water is used to clean the material and cool the blades during crushing. Large materials are processed into small pieces in this module, which improves the washing result and makes the final product easy to pack.

Floating Washer

The sediment and metal in the material can be effectively separated through this module to protect the environment from pollution.

Material: stainless steel.

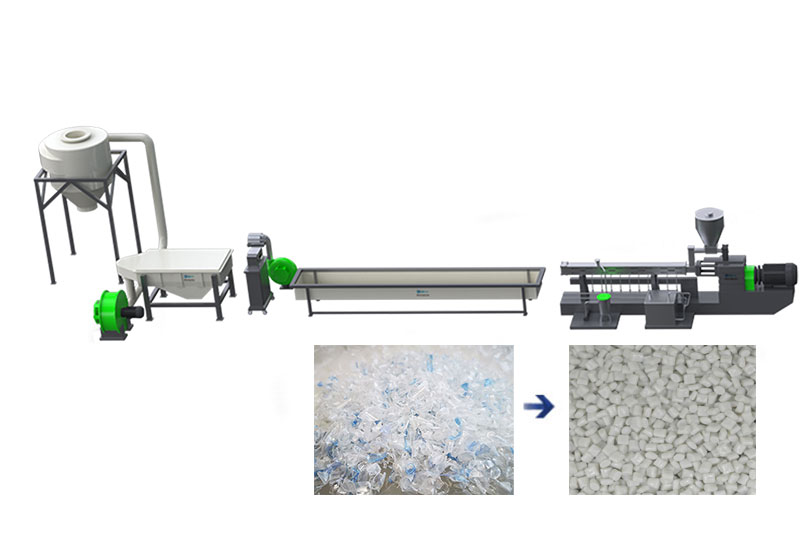

Dewatering Machine

Advanced dewatering vibration sieves and horizontal-type centrifugal dewatering present high-performance dried pellets and lower energy consumption. Combining crushing, compacting, and pelletizing steps in one system results in less labor cost: higher efficiency feeding, higher output, and lower energy consumption.

Why Chose Us?

1. Reliable parts and supplier to ensure the quality

2. With more than 15years comprehensive experience, Highly skilled artisan together with modern processing methods ensure that ABLE has stable and high performance products.

3. Specially designed structure ensure the quality ,steady ,long life ,performance

4. Many leading companies in different industries have cooperated with us ,such as shengqili group(listed company) ,ALBIS PLASTIC GMBW ,TRUPER group mexico,Colormax group ,Green recycle Lebanon .

5. Rapid-response within 24hours

6. 100% raw material from ISO certified factory

7. 18 Months warranty

8. Engineers at your service anytime .

9. One -step purchasing supplier

Reviews

There are no reviews yet.