Video

Machine Parameters

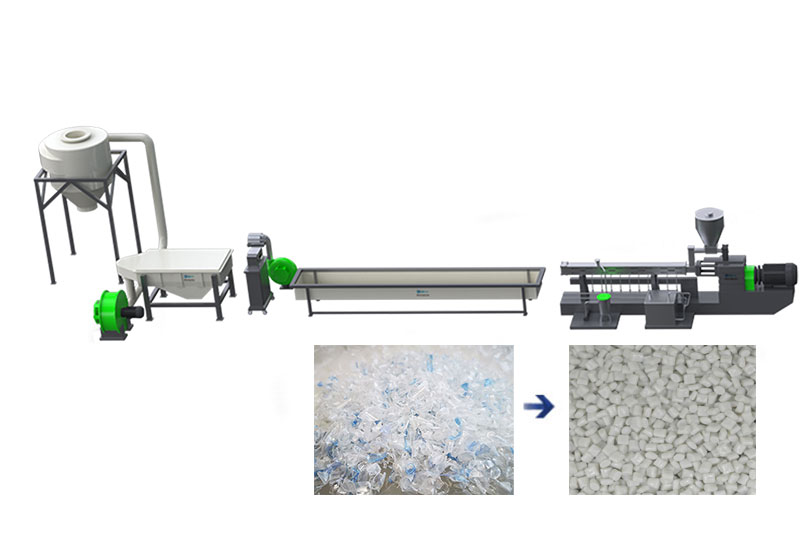

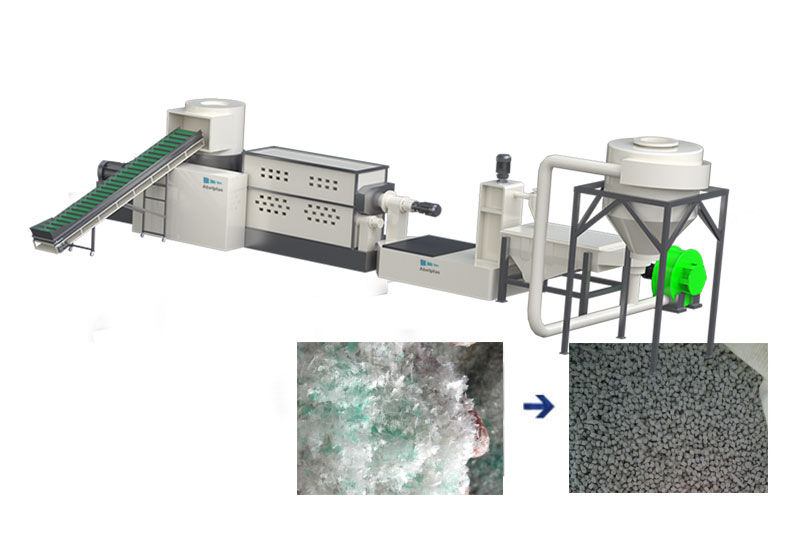

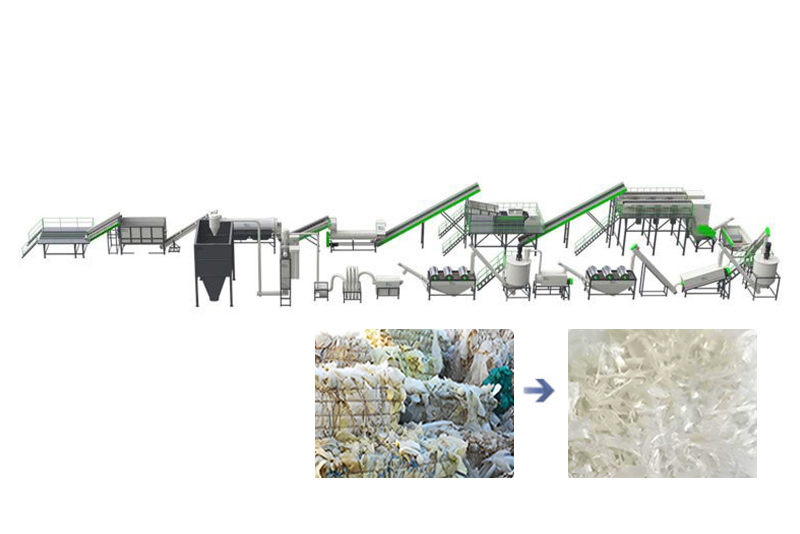

Production Lines Flow Chart

Granulator

● Cutting Tools: Typically equipped with blades to cut the long PET material into uniform small pellets.

● Automation System: The granulator machine can be automatically connected with other parts of the production line to ensure continuity and efficiency in the cutting process.

● Adjustment System: Allows adjustment of the cutting length to meet the requirements for different pellet sizes.

● Mobility: The equipment is usually designed with wheels for easy movement within the production workshop.

Cooling Water Baths

● Cooling Method: Uses cold water to quickly lower the temperature of PET pellets.

● Uniform Solidification: Ensures even cooling and prevents pellets from sticking together.

● Fast Process: Quickly solidifies molten PET, improving production efficiency.

● Types: Can be designed for continuous or batch cooling depending on production scale.

Extruder

● Feeding Hopper: Used to load the raw PET pellets into the extruder.

● Screw and Barrel: The rotating screw mixes, heats, and melts the raw material.

● Die Head: The molten PET is extruded through the die head, which can be designed to produce products in different shapes.

● Drive Motor: Provides the necessary power to rotate the screw.

● Control System: Used to adjust process parameters such as temperature and speed to ensure product quality.

Cooling Unit

● Cooling Function: The extruded hot molten PET material passes through this cooling unit and comes into contact with cooling water, which rapidly reduces its temperature and forms stable solid pellets or strands.

● Stainless Steel Material: The unit is typically made of stainless steel to prevent corrosion and maintain cleanliness.

● Water Circulation System: There may be a water circulation system inside to maintain a constant temperature and flow rate, enhancing cooling efficiency.

● Structural Design: The design allows the molten material to evenly contact the cooling water, achieving optimal cooling results.

Why Chose Us?

1. Reliable parts and supplier to ensure the quality

2. With more than 15years comprehensive experience, Highly skilled artisan together with modern processing methods ensure that ABLE has stable and high performance products.

3. Specially designed structure ensure the quality ,steady ,long life ,performance

4. Many leading companies in different industries have cooperated with us ,such as shengqili group(listed company) ,ALBIS PLASTIC GMBW ,TRUPER group mexico,Colormax group ,Green recycle Lebanon .

5. Rapid-response within 24hours

6. 100% raw material from ISO certified factory

7. 18 Months warranty

8. Engineers at your service anytime .

9. One -step purchasing supplier

Reviews

There are no reviews yet.