Video

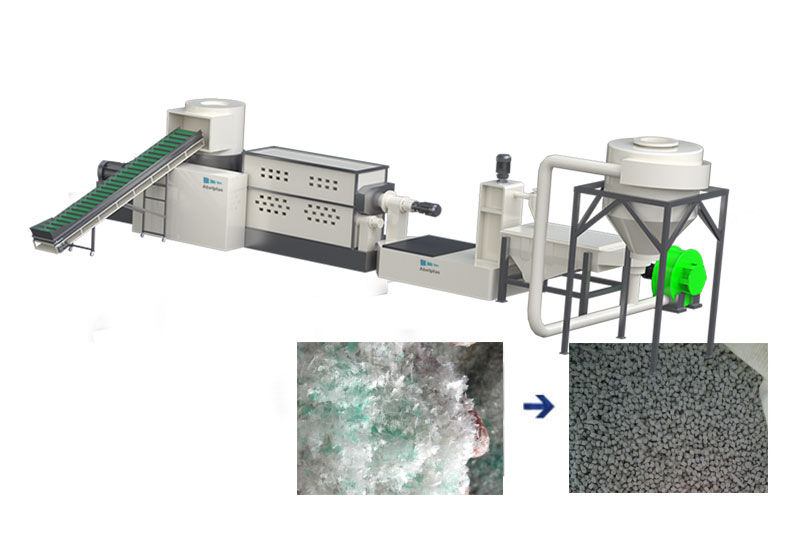

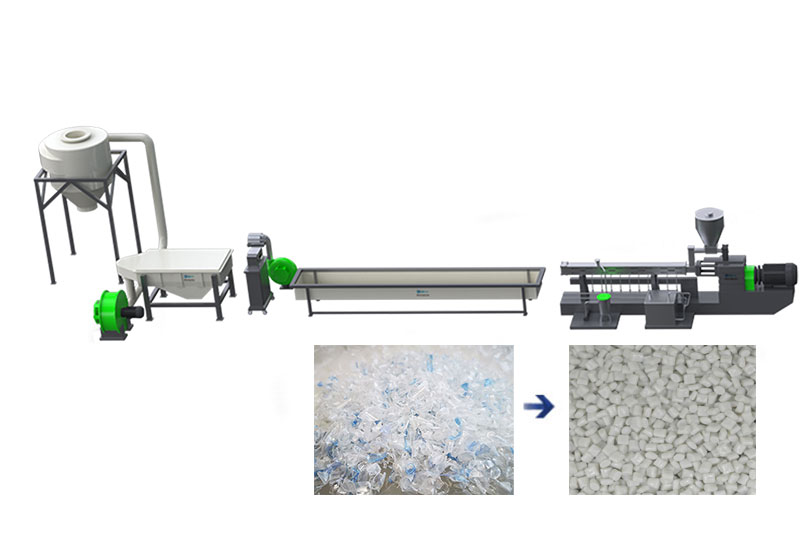

PP PE Film Pelletizing Line Detailed Image

Machine Parameters

Workflow

Features:

This PP PE film pelletizing line is special for PE PP film recycling pelleting.

It includes compacting machine which compacts the film into smaller granules, this lets the film easily feed into the screw barrel of the single extruder.

The efficiency is high and it can improve the production capacity and save labor costs.

Our machinery can make two vacuum-exhausting mouths on extruder barrels which can fully vent the moisture in the material according to the customer's requirements.

| Model | SJ90 | SJ100 | SJ120 | SJ150 |

| extruder screw diameter | 90 | 100 | 120 | 150 |

| main motor of the compacting machine (kw) | 37 | 55 | 75 | 90 |

| production capacity(kg/h) | 100-150 | 200-300 | 300-400 | 500-600 |

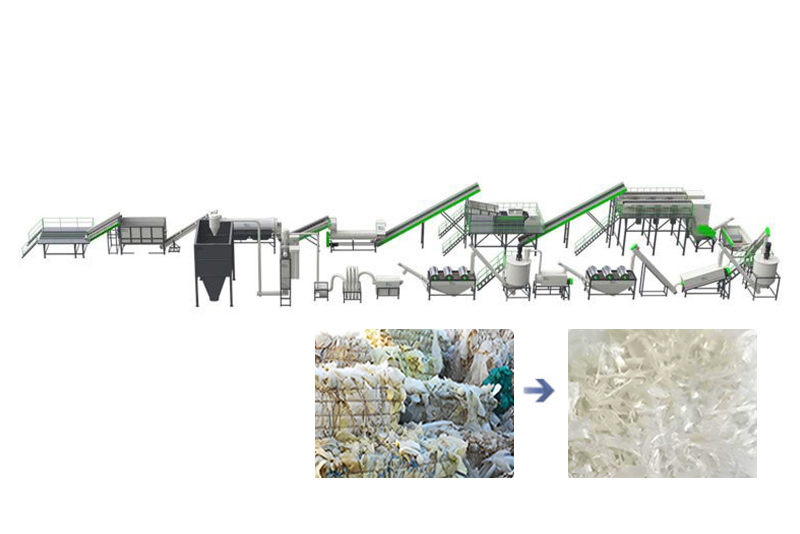

PP PE Film Pelletizing Production Line Flow Chart

Belt conveyor

● Material Transport: Efficiently transfers raw materials and intermediate products.

● Increased Efficiency: Reduces manual handling and boosts production efficiency.

● Optimized Production Flow: Ensures smooth connection between processes.

● Reduced Material Loss: Minimizes material spillage during transportation.

● Flexibility : Adjustable length and incline to meet specific needs.

Dewatering

● Moisture Removal: Dewatering effectively removes excess moisture from washed materials, preparing them for the extrusion process.

● Drying Efficiency: Reducing moisture content enhances overall drying efficiency, ensuring the feed material is suitable for processing.

● Energy Savings: Performing dewatering before drying can save energy and reduce associated costs.

● Contaminant Separation: Some dewatering equipment can help separate contaminants from the materials, ensuring cleaner input for the granulation process.

Single extruder

● Simplicity: Features a straightforward design that is easy to operate and maintain

● Cost-Effective: Lower initial investment and operational costs compared to multi-extruder setups.

● Efficient Processing: Capable of delivering consistent material output for various applications.

● Versatility: Suitable for processing a wide range of polymer materials, including PE and PP.

● Compact Size: Occupies less floor space, making it ideal for smaller production facilities.

Vibrator

● Material Flow Aid: A vibrator helps facilitate the smooth flow of materials through hoppers and chutes, preventing clogs and ensuring even feeding.

● Uniformity in Processing: Promoting uniform material distribution, it ensures consistent feeding into the granulation or extrusion equipment.

● Particle Separation: Vibrators can assist in separating fines or unbonded materials from larger particles, enhancing the quality of the feedstock.

● Cost Efficiency: Improving material flow and reducing downtime minimizes operational costs and enhances productivity in the processing line.

● Adjustable Settings: Many vibrators offer adjustable frequency and amplitude settings, allowing for customization based on specific material properties and processing needs.

Why Chose Us?

1. Reliable parts and supplier to ensure the quality

2. With more than 15years comprehensive experience, Highly skilled artisan together with modern processing methods ensure that ABLE has stable and high performance products.

3. Specially designed structure ensure the quality ,steady ,long life ,performance

4. Many leading companies in different industries have cooperated with us ,such as shengqili group(listed company) ,ALBIS PLASTIC GMBW ,TRUPER group mexico,Colormax group ,Green recycle Lebanon .

5. Rapid-response within 24hours

6. 100% raw material from ISO certified factory

7. 18 Months warranty

8. Engineers at your service anytime .

9. One -step purchasing supplier

Reviews

There are no reviews yet.