Video

Detailed Image

Machine Parameters

Features

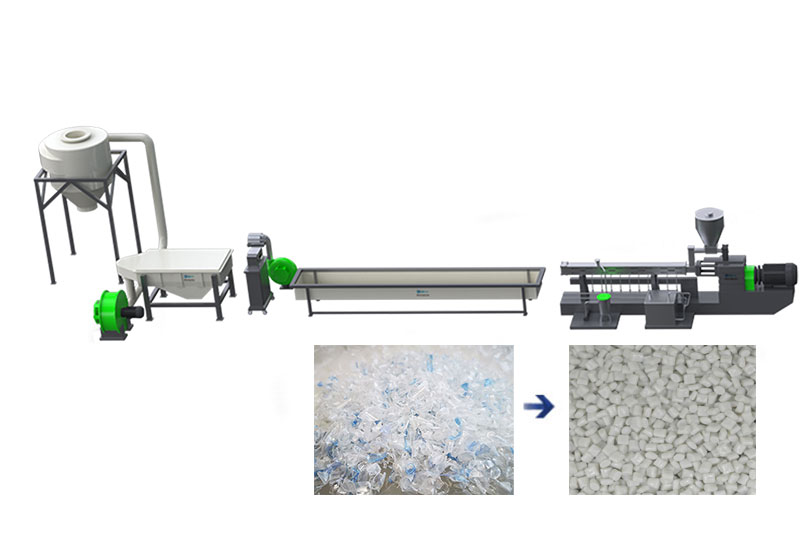

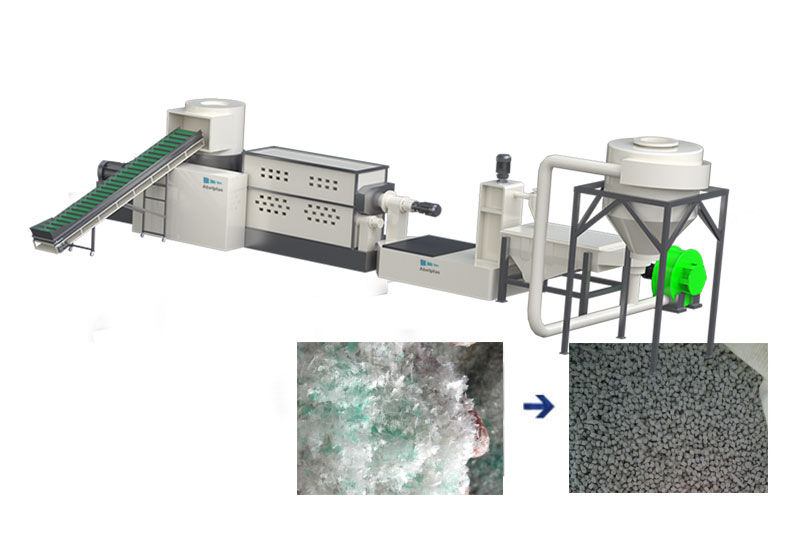

1. This compaction granulator is dedicated to PE PP hard material/flake recycling granulation.

2. Forced feeding, which can compact the flakes into smaller particles, so that the flakes can be easily fed into the screw barrel of the single extruder.

3. High efficiency, which can increase production capacity and save labor costs.

4. The machine can make vacuum exhaust ports on the extruder barrel according to customer requirements, which can fully discharge the moisture in the material.

Process flow

1. feeding conveyor → 2. force feeding → 3. screw extruder → 4. hydraulic screen changer → 5. pelletizing system → 6. water cooling → 7.air dryer → 8.vibration screen → 9. drying system → 10. store silo

| Hard Material Plastic Recycling Pelletizing Line | ||||

| Model | SJ90 | SJ100 | SJ120 | SJ150 |

| Extruder screw diameter | 90 | 100 | 120 | 150 |

| The main motor of the compacting machine (kw) | 37 | 55 | 75 | 90 |

| Production capacity(kg/h) | 100-150 | 200-300 | 300-400 | 500-600 |

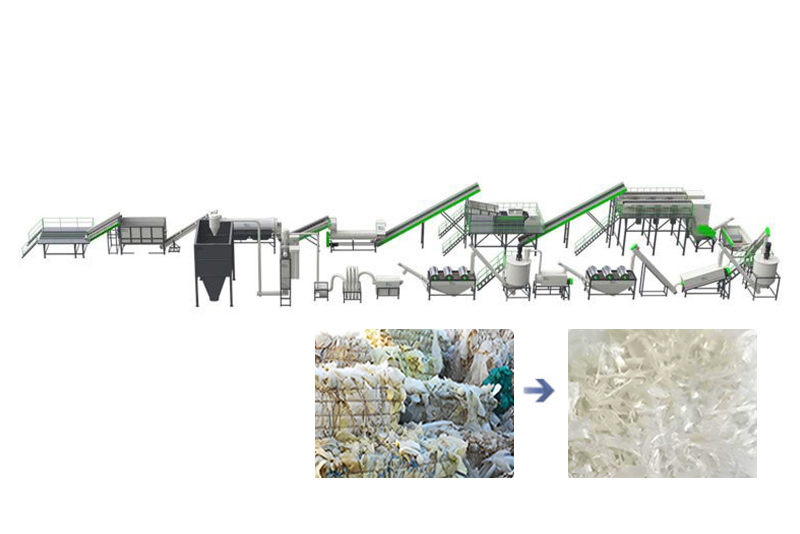

Production Lines Flow Chart

Feeding conveyor

Function: Used to evenly and continuously convey raw materials (such as crushed plastic granules or plastic flakes) to the entrance of the main granulator machine.

Features:

The high degree of automation reduces manual intervention.

Adjustable conveying speed to ensure stable operation of subsequent processes.

Pelletizing system

Function: Cut the molten plastic into pellets after extruding it through the die head.

Features:

Precise cutting to ensure pellet uniformity.

The pelletizing speed is synchronized with the die head extrusion speed.

Water cooling system

Function: Rapidly cool the high-temperature plastic particles after pelletizing to prevent particles from sticking and keep the shape stable.

Features:

Significant cooling effect and easy operation.

Temperature control devices can be selected as needed

Air Dryer

Function: Remove moisture from the surface of plastic particles to ensure easy storage and use after drying.

Features:

Fast drying speed and high efficiency.

Can be equipped with a filter device to prevent dust pollution.

Why Chose Us?

1. Reliable parts and supplier to ensure the quality

2. With more than 15years comprehensive experience, Highly skilled artisan together with modern processing methods ensure that ABLE has stable and high performance products.

3. Specially designed structure ensure the quality ,steady ,long life ,performance

4. Many leading companies in different industries have cooperated with us ,such as shengqili group(listed company) ,ALBIS PLASTIC GMBW ,TRUPER group mexico,Colormax group ,Green recycle Lebanon .

5. Rapid-response within 24hours

6. 100% raw material from ISO certified factory

7. 18 Months warranty

8. Engineers at your service anytime .

9. One -step purchasing supplier

Reviews

There are no reviews yet.